Understanding Axial Fan Operation and Design

Fundamental Principles of Axial Airflow

Axial fans work because they move air along the same line as their spinning axis. Basically, the air flows straight through the fan rather than around it like other types do. What makes them so good at moving air efficiently? They actually take advantage of something called Bernoulli's principle. When air speeds up, the pressure drops, and this helps push more air through the system. That's why many building ventilation systems rely heavily on axial fans. For instance, in commercial HVAC setups, switching to axial fans often means big reductions in electricity bills. Industry numbers suggest businesses can save anywhere from 20% to 30% on power costs when they make the switch. These savings aren't just good for company budgets either they also mean fewer carbon emissions overall, making axial fans an environmentally smart choice too.

Core Components: Blades, Hub, and Motor Systems

Axial fans basically have three main parts: blades, a hub, and various motor systems. Each part plays its own role in how well the fan performs overall. The blades themselves come in different shapes and angles depending on what kind of airflow is needed. Their design really affects how much air moves through the system and just how efficient the whole thing runs. Then there's the hub, which holds everything together at the center point. A good quality hub makes sure the fan stays sturdy during operation while also affecting how noisy it gets and directing where the air flows. Motor systems vary too from standard AC blowers to specialized exhaust fan motors. These motors determine most of the airflow output since they drive the entire mechanism forward. When all these pieces fit properly together, they create the kind of airflow performance we expect from modern axial fan systems across industrial and commercial settings.

How Axial Fans Differ from Centrifugal Alternatives

Axial and centrifugal fans are pretty different when it comes to how they handle air movement and where they work best. Axial models push air straight through, which works great for situations where there's not much resistance but lots of volume needed. Centrifugal fans take a different approach altogether, creating pressure as air moves around the fan blades. Because of this radial pressure increase, centrifugal fans tend to perform better in settings where higher pressure is required. Getting this right matters a lot for companies trying to pick between options. Space limitations and budget concerns often play a big role too. When manufacturers choose the right kind of fan for their specific setup, they typically see improvements in day-to-day operations while also cutting down on electricity bills over time.

Key Performance Features of Axial Fans

Energy Efficiency and Low Power Consumption

Axial fans really shine when it comes to energy efficiency and power usage, especially when stacked against other fan options on the market. For factories and plants where ventilation systems need to stay running all day every day, this matters a lot. When manufacturers install modern motor tech like those AC blower motors, they often see around 35-40% drops in yearly electricity bills, which helps green initiatives too. Take HVAC systems for example, since these units typically operate non-stop throughout the year, saving on energy isn't just nice to have anymore it's practically essential for staying competitive. Companies that switch to these efficient axial models save money month after month while doing their part for the planet at the same time.

High Airflow Capacity in Compact Designs

Axial fans stand out because they can move massive amounts of air, sometimes reaching around 60 thousand cubic feet per minute despite their relatively small size. They work really well in tight spots where there isn't much room to spare, think about city buildings or factories with cramped machinery areas. What makes these fans so useful is how easily they fit into current ventilation setups without requiring major overhauls or expensive changes to existing infrastructure. With both strong performance numbers and compact build, axial fans have become go to solutions across various HVAC projects, especially when getting maximum airflow through restricted spaces matters most for proper climate control.

Noise Reduction Capabilities

Axial fans today come with all sorts of features that cut down on noise levels quite a bit, which makes them work well in places where loud noises would be a problem. Some studies point out that certain models can actually lower noise by around 10 decibels, creating spaces that feel much quieter overall. Manufacturers achieve this by tweaking designs like blade shapes that follow air flow better and improving motors so they run smoother. Whether installed at home or in offices, these quieter fans do more than just make things sound nicer they help businesses stay within those workplace noise regulations that many industries have to follow. A restaurant kitchen, for instance, benefits greatly from reduced fan noise while still getting proper ventilation.

Diverse Industrial Applications of Axial Fans

HVAC Systems: AC Blower Motor and Condenser Cooling

Axial fans play a really important role in HVAC systems, especially when they're used as AC blower motors. These fans help move air around effectively and keep things cool inside buildings, something people definitely appreciate during hot summer days. The way these fans work allows them to push large volumes of air quickly through condensers, which helps prevent components from getting too hot and actually makes the whole system run better. Research indicates that putting axial fans into HVAC units tends to boost performance quite a bit while cutting down on electricity bills at the same time. Longer lasting equipment means fewer repairs and replacements over time, making these fans worth considering for homes as well as businesses that need reliable climate control solutions without breaking the bank on maintenance costs.

Ventilation and Exhaust Solutions Across Industries

Axial fans are pretty much everywhere these days across different sectors like factories and restaurant kitchens where they help keep the air clean. These fans work well at getting rid of smoke, excess heat, and bad smells, making sure workers don't breathe in harmful stuff while also meeting basic safety requirements. Some studies show that when properly installed, these specialized exhaust systems can cut down on indoor pollution levels by around half in spaces that aren't very open. That kind of improvement makes a big difference in how healthy people feel at work and whether companies stay within regulatory limits. No wonder so many businesses rely on them for managing air quality issues day after day.

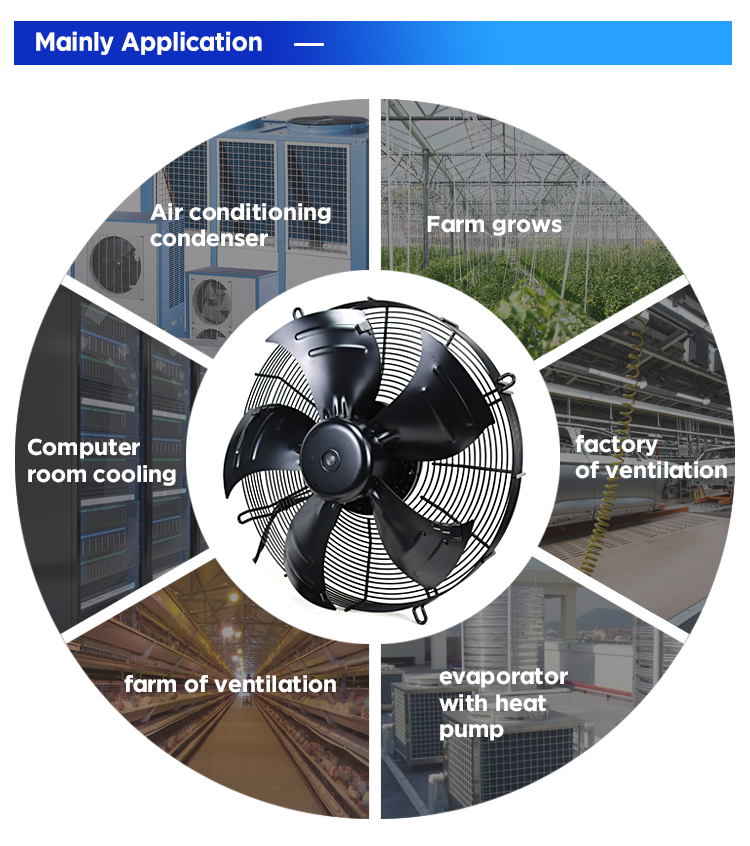

Specialized Uses: Data Centers and Agricultural Environments

Axial fans play a critical role in data centers by keeping things cool enough to stop expensive equipment failures. Most facilities can't run without these fans providing constant airflow throughout server rooms. Beyond tech spaces, farmers also depend on axial fans in their operations. Greenhouse growers use them to regulate temperature and humidity levels while dairy farms install similar systems to ensure proper air circulation for cattle health. What makes axial fans so valuable across different industries is how well they work in multiple settings, from high-tech server rooms to barns and greenhouses. They handle everything from precise temperature control to basic ventilation tasks pretty much anywhere someone needs controlled airflow.

Selection and Maintenance Guidelines

Matching Axial Fan Specifications to Application Needs

Getting the right axial fan means matching key specs like airflow rates, pressure compatibility, and how much power it consumes against what the system actually needs. Take time to look at all these aspects before making a decision since getting it wrong really affects how well everything works together. Talking directly with manufacturer reps often gives real world perspective on what fans work best under different conditions, which helps get better results over time. When specs don't match up properly, expect higher running costs down the road plus possible wear and tear on other components too. Following good selection practices isn't just about saving money though; it keeps systems running smoothly without unexpected breakdowns that disrupt operations.

Routine Maintenance Procedures for Optimal Performance

Keeping up with regular maintenance work is essential if axial fans are going to perform at their best. Cleaning those fan blades and giving the motor systems a good check will help extend the lifespan of equipment while keeping things running smoothly. Putting together a proper maintenance plan helps avoid surprises when fans break down unexpectedly, which saves money in the long run. Most experienced technicians recommend looking at axial fans somewhere between six to twelve months apart, though heavy duty applications might need more frequent checks. Following this kind of schedule ensures consistent airflow output from the fans, which keeps entire systems operating efficiently without unnecessary energy waste or performance drops.

Troubleshooting Common Operational Issues

Troubleshooting those everyday problems with fans - vibrations, strange noises, or weird airflow patterns - saves money in the long run by avoiding expensive fixes and downtime. When technicians spot these issues early and know how the fan actually works, they can tell pretty quickly if something needs adjusting, maybe realigning blades or swapping out a worn blower motor. Keeping track of what goes wrong repeatedly and how it got fixed helps build this sort of internal knowledge base over time. The shop floor guys really appreciate having that history when similar problems pop up again. Taking this hands-on approach means axial fans last longer and run better, which everyone agrees is worth the extra effort upfront.