SEER2 Mandates and What They Mean for Air Conditioner Motor Efficiency

How the 2023–2024 DOE SEER2 Update Raises the Bar for Air Conditioner Motor Performance

Starting in January 2023, the Department of Energy rolled out new SEER2 standards that test air conditioning units under conditions closer to what people actually experience in their homes. These tests factor in things like increased static pressure and different outdoor temperatures throughout the year. What this means for everyone is that the baseline efficiency standards have gone up between 8% and 15% depending on where someone lives, and it's basically saying goodbye to those old single speed PSC motors that weren't very efficient anyway. Systems that meet these requirements need to use variable speed technology instead. We're talking about Electronically Commutated Motors (ECMs) and Permanent Magnet Synchronous Motors (PMSMs). The good news? These newer motor types save anywhere from 30% to 50% more energy compared to older models because they adjust airflow based on actual cooling needs rather than just running at full blast all the time. This cuts down on wasted electricity, reduces how often the system turns on and off, and keeps performance steady even when not operating at maximum capacity.

Regional Compliance Breakdown: Why Air Conditioner Motor Selection Varies Between Northern and Southern U.S. Markets

SEER2 enforces climate-specific efficiency thresholds, directly shaping motor technology selection:

| Region | Minimum SEER2 Requirement | Motor Technology Preference |

|---|---|---|

| Northern U.S. | 13.4 | Cost-optimized ECMs |

| Southern U.S. | 14.3 (split systems) | High-torque PMSMs |

Northern markets typically have shorter cooling periods and less intense peak demand, so moderate efficiency ECM motors generally satisfy regulatory requirements while keeping initial costs reasonable compared to their performance. Southern regions tell a different story though. The equipment there runs through extended hot weather cycles, making PMSM motors a better fit because they handle heat much better (they can operate at around 158 degrees Fahrenheit), produce more torque for their size, and maintain efficiency even when working hard over long periods. When picking out motors, it's important to match what the specs say with actual climate conditions in each area. Plus, nobody wants headaches later on, so checking off all the boxes in DOE's 10 CFR Part 430 certification rules makes sense for anyone serious about compliance issues down the road.

High-Efficiency Air Conditioner Motor Technologies: ECMs, PMSMs, and Regulatory Readiness

ECM vs. Permanent Magnet Synchronous Motor (PMSM): Efficiency, Cost, and DOE Certification Fit

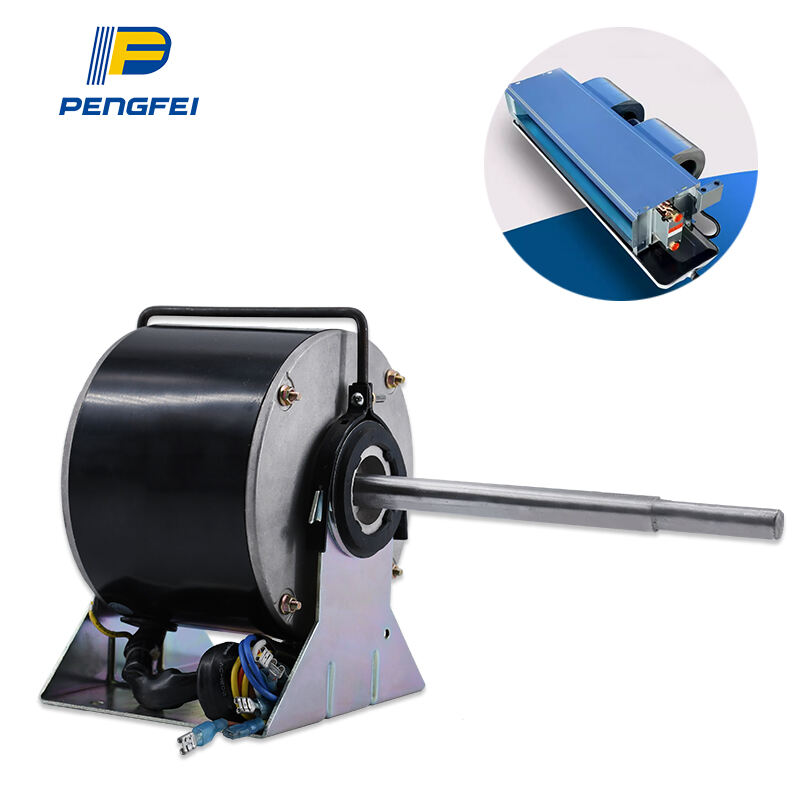

In modern HVAC systems that meet compliance standards, ECMs and PMSMs stand out as the top choices for efficient motor operation. The ECM technology works by using built-in inverters and microprocessors to switch AC power into DC format, which allows for very accurate speed adjustments without needing brushes. This results in around 85% efficiency rates, way better than the roughly 65% we see from older PSC motors. When looking at PMSMs though, they take things one step ahead. These motors incorporate neodymium magnets that pack more power into smaller spaces while staying cool even when pushed hard. They keep performing well at higher temps too. Sure, PMSMs come with about a 15 to 20 percent price tag increase over ECMs, but many facilities find that the longer lifespan and reliable performance in places where these motors run constantly makes up for the extra cost pretty quickly. Both options work fine with current SEER2 regulations set forth in 10 CFR Part 430, yet PMSMs give manufacturers more flexibility if regulations get stricter down the road because of how well they handle heat and deliver strong torque output.

Real-World Impact: How Upgrading the Air Conditioner Motor Boosts System SEER by 1.5–2.2 Points

Switching over to ECM or PMSM motors can actually boost system level SEER ratings anywhere from 1.5 to around 2.2 points. This isn't just about small improvements either—it fundamentally changes how the whole system handles workload. These variable speed motors get rid of those big energy jumps that happen when fixed speed compressors kick on. Instead they adjust airflow constantly based on what's needed at any given moment. Think about it—most systems spend about 70% of their time running at partial capacity in typical US weather conditions. That makes this kind of flexibility really important for efficiency. According to field tests we've seen, these motor upgrades typically lead to noticeable improvements in SEER performance across different installations.

- Maintaining optimal airflow with consistent torque delivery, reducing duct losses

- Cutting compressor cycling losses by 40–60%

- Lowering parasitic fan power consumption

The result is 18–25% lower annual energy use and reduced thermal stress on components—extending overall system lifespan.

Beyond SEER2: Integrating Air Conditioner Motor Efficiency with EER, HSPF, and System-Level Compliance

SEER2 gives us a baseline for seasonal cooling efficiency, but what really matters for system performance is how well the motor handles everything from EER to HSPF. Take EER first—it looks at peak efficiency when temps hit 95 degrees outside. That's when the motor needs to respond properly even with high static pressure and warm ambient conditions so power consumption doesn't spiral out of control. Then there's HSPF, which checks heating efficiency throughout winter months. The motor has to maintain steady, low speed operation during those tricky defrost cycles and when temps drop below freezing. Good motors actually boost both numbers because they cut down on wasted energy spikes and keep airflow consistent no matter what extremes we throw at them. We've seen cases where motors look great on paper for SEER2 ratings but fall apart in real world heat scenarios, failing to meet minimum EER requirements. Same thing happens with heat pumps whose HSPF scores tank if the motor struggles with consistent low speed control. Smart manufacturers know this and test their motors against all three standards rather than focusing solely on SEER2 certification. After all, nobody wants systems that perform well in lab tests but crash and burn during actual installation seasons.

Selecting a Compliant Air Conditioner Motor: A B2B Procurement Checklist

Verifying 10 CFR Part 429/430 Certification and Third-Party Test Reports

When specifying motors, make sure they have certification under the latest DOE regulations (10 CFR Part 429/430) that confirms compliance with those new 2023-2024 SEER2 requirements everyone keeps talking about. Always double check what manufacturers submit by looking at independent lab reports too. These should come from labs accredited by NVLAP or holding ISO/IEC 17025 certification. The key thing is these reports need to show actual efficiency measurements hit the right standards for different regions. Northern states generally require at least 13.4 SEER2 while down south where split systems are common, the bar sits higher at 14.3 SEER2. And don't forget to verify when the testing happened either. Labs should have done this work no more than 18 months ago so everything lines up with the most recent testing methods and equipment specs we've got today.

OEM Compatibility, Thermal Management, and Long-Term Reliability in Variable-Speed Applications

Before installing any new components, check if they match the dimensions, voltage requirements, and communication protocols of existing OEM equipment to avoid those frustrating integration problems down the road. When dealing with variable speed systems where motors run through broad RPM ranges over long periods, thermal resistance becomes absolutely critical. Motor specs should include things like enhanced cooling fins, sealed windings against moisture damage, or built-in temperature monitoring capabilities. According to field data analysis, motors that can't properly dissipate heat tend to fail around 30% more frequently once they hit about 15,000 operating hours. For installations in challenging conditions like coastal areas, warehouses with dust issues, or places prone to humidity, it's wise to specify motors with at least 100,000 hour life expectancy ratings and IP54 protection minimum. These factors really make a difference in maintaining performance levels over time.

FAQ Section

What are SEER2 standards?

SEER2 standards are updated energy efficiency metrics set by the Department of Energy to reflect real-world operating conditions for air conditioners. They aim at improving baseline efficiency and promote advanced motor technologies.

What technologies are replacing PSC motors?

PSC motors are being replaced by variable speed technologies such as Electronically Commutated Motors (ECMs) and Permanent Magnet Synchronous Motors (PMSMs), which offer higher energy savings.

Why do SEER2 standards vary by region?

SEER2 standards vary by region to account for climate-specific demands. Different regions experience varying weather patterns affecting air conditioning intensity, thereby influencing motor selection.

How do ECMs and PMSMs improve efficiency?

ECMs and PMSMs improve efficiency by adjusting airflow according to cooling needs, reducing wasted electricity, and optimizing system performance even at partial capacity.

Why should motors meet EER and HSPF along with SEER2?

SEER2 provides a baseline for cooling, but EER and HSPF cover peak performance and heating efficiency during challenging conditions, ensuring comprehensive motor performance evaluation.

What does 10 CFR Part 429/430 Certification entail?

10 CFR Part 429/430 Certification verifies motor compliance with DOE regulations, ensuring energy efficiency standards are met based on independent lab tests.

Table of Contents

- SEER2 Mandates and What They Mean for Air Conditioner Motor Efficiency

- High-Efficiency Air Conditioner Motor Technologies: ECMs, PMSMs, and Regulatory Readiness

- Beyond SEER2: Integrating Air Conditioner Motor Efficiency with EER, HSPF, and System-Level Compliance

- Selecting a Compliant Air Conditioner Motor: A B2B Procurement Checklist

- FAQ Section