Growing Industrial Demand for Induction Motors

Market Trends: Rising Adoption of Induction Motors Across Sectors

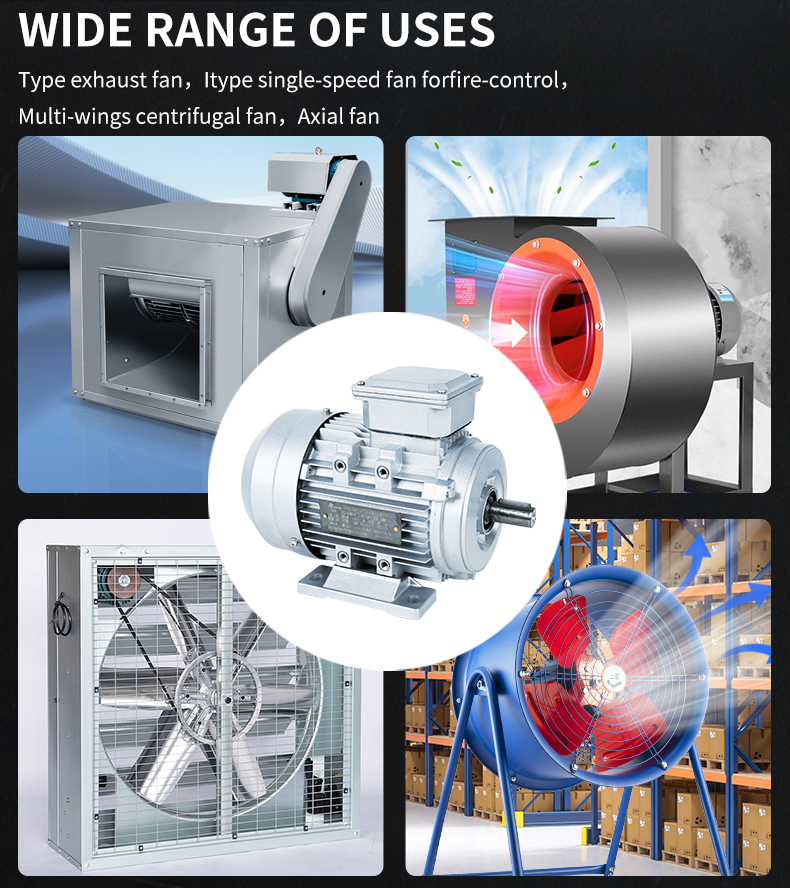

Global markets for induction motors are expected to expand quite significantly, growing around 7.2% annually until 2035. This growth comes from industries going electric and wanting better energy efficiency. Industries such as heating systems, mines, and car factories depend heavily on these motors because they handle changing workloads and tough conditions pretty well. The Asia Pacific region stands out when it comes to adopting this technology. According to data from the Asian Development Bank released in 2024, this area already accounts for about 60% of all industrial energy used worldwide. Many governments there have started requiring IE3 compliant motors as part of efforts to cut down on wasted power.

| Market Outlook | 2025 | 2035 |

|---|---|---|

| Market Value | $24.7 billion | $49.4 billion |

Key Drivers: Energy Efficiency, Reliability, and Regulatory Support

Energy efficiency standards such as IE3 and IE4 are now covering about 85 percent of all industrial motor sales across G20 countries according to IEC data from 2023. These induction motors cut down on wasted energy somewhere between 15 to maybe even 30 percent when compared with older models. Plus they need around forty percent fewer repairs throughout their ten year lifespan as shown by Ponemon Institute research back in 2023. Places like India have pushed things along too with their requirement that any new industrial setup must include at least IE3+ rated motors. This kind of regulation definitely speeds up how fast these better performing motors get adopted industry wide.

Case Study: Automotive Manufacturing’s Shift to Induction Motor Systems

A leading automotive plant in Germany achieved 22% energy savings by replacing legacy motors with IE4-compliant induction variants. The upgrade reduced downtime by 300 hours annually, demonstrating how induction motors enhance both sustainability and operational reliability in high-throughput environments.

Global Outlook: Increasing Demand for IE3 and IE4 Compliant Motors

By 2030, 90% of EU industrial motors must meet IE4 standards under the Ecodesign Directive. Emerging economies are following suit, with Southeast Asian nations prioritizing IE3 adoption to align with carbon-reduction targets. This global shift underscores induction motors’ critical role in achieving industrial decarbonization and smart manufacturing objectives.

Core Advantages of Induction Motors in Industrial Use

Robust Design and Durability in Harsh Operating Conditions

Induction motors used in industrial settings are built tough with minimal moving components, which means they can handle pretty much anything thrown at them from scorching heat to damp conditions and dust filled air. The absence of brushes in these motors cuts down on wear and tear caused by friction, so they tend to last much longer in places where equipment failures cost money and time. Take the mining industry for instance. Conveyor belt motors running in quarries typically last around 30 percent longer compared to older brushed models simply because there's no carbon brush wear to contend with over time. This reliability makes a big difference when downtime translates directly into lost production.

Low Maintenance Needs Compared to Alternative Motor Types

Induction motors don't have those pesky commutators or slip rings that need replacing all the time, which means they save around 45% on maintenance expenses when compared against traditional DC motors. The inclusion of automated lubrication systems along with sealed bearings really makes a difference too, pushing service intervals way beyond what most manufacturers expect - often reaching over 10,000 operational hours in standard factory environments. And let's face it, this kind of reliability matters a lot. Just look at automotive plants where every minute lost in production translates to serious money down the drain. Some studies show delays can cost upwards of $740 thousand per hour according to Ponemon research from last year.

Long-Term Cost Savings and Operational Reliability

Energy-efficient IE3-class induction motors save facilities $18,000 annually per 100 HP unit through reduced power consumption. Their simple speed-torque characteristics minimize the need for complex control systems. Over a 15-year lifecycle, industrial users report 60% lower total ownership costs versus synchronous motor alternatives when factoring in energy, maintenance, and downtime expenses.

Uninterrupted Performance in Mission-Critical Applications

Advanced thermal protection systems allow induction motors to sustain 110% overload capacity for 30 minutes—critical for steel mills managing sudden load spikes during rolling operations. Backup cooling mechanisms and surge-resistant windings ensure continuous operation in oil refineries where unexpected motor failures could trigger safety shutdowns costing $2.4M/day.

Energy Efficiency and Sustainability Impact

Efficiency Standards (IE3, IE4) Shaping Industrial Motor Selection

The international efficiency (IE) rating system has become pretty much standard across industries these days. IE3 (known as Premium Efficiency) and IE4 (or Super Premium Efficiency) motors account for around 68% of all industrial motor purchases worldwide according to Global Efficiency Intelligence data from last year. These ratings work hand in hand with tough regulations like the EU's Ecodesign rules from 2021 and the US Department of Energy's Title 20 standards. What makes these efficiency standards worth the switch? They cut down on wasted energy during conversion processes by roughly between 9 and 15 percent when compared to older motor models. Recent research published in Power Transmission Monthly back in 2023 showed that companies investing in IE4 compliant induction motors can expect their money back within just twelve months, especially at facilities running non-stop operations such as those massive bottling plants that never shut down.

Reducing Energy Consumption in Manufacturing Processes

Steel mills that switch to IE3 or IE4 induction motors see around 18% less energy consumption per ton during their rolling mill operations. That's pretty impressive when we consider process heating alone takes up nearly half (about 53%) of all energy costs across the industry, as noted by the International Energy Agency in 2023. Looking at automotive manufacturing facilities, there's been some serious savings too. When they upgraded from old brushed DC motors to these new sensorless vector controlled induction motors for their HVAC systems, electricity usage dropped by almost 70%. A study covering twelve plants throughout North America confirmed these results, showing just how impactful modern motor technology can be on operational costs.

Supporting Carbon Reduction and ESG Goals with High-Efficiency Motors

With 44% of Fortune 500 manufacturers targeting carbon-neutral operations by 2030, IE4 induction motors eliminate 1.2 million metric tons of CO2 annually through reduced grid dependence in compressor and pump applications. This performance supports ESG frameworks like SASB’s IF-EU-410a.7 standard, which ties 23% of industrial ESG scores directly to energy-efficient equipment deployment.

Key Efficiency Gains Across Sectors

| Application | IE3 vs. Legacy Motors | IE4 vs. IE3 Motors |

|---|---|---|

| Water Pumps | 12–14% energy savings | Additional 5–7% |

| Conveyor Systems | 8–11% energy savings | Additional 3–5% |

| Ventilation Fans | 15–18% energy savings | Additional 6–9% |

(Data: Global Efficiency Intelligence 2023 Benchmark)

Technological Innovations Enhancing Induction Motor Performance

Integration with Variable Frequency Drives for Precision Control

These days, most modern induction motors come with variable frequency drives (VFDs) attached. The reason? They allow for much finer control over speed and torque than traditional setups. When paired together, this combo can cut down on energy usage quite a bit actually around 30% in places like conveyor belts and pump stations where the workload keeps changing all the time. What makes this work so well is that VFDs adjust the motor's power output right as needed instead of running at full blast constantly which wastes tons of electricity. Companies that switched to these systems report seeing their return on investment happen between 18 to maybe even 22 percent quicker because they spend less money fixing breakdowns and paying those hefty electric bills month after month.

Advanced Control Methods: Vector and Sensorless Technologies

Induction motors are catching up to permanent magnet motors when it comes to precision work such as CNC machining and robotic applications thanks to vector control algorithms. The key innovation here is separating torque from flux control, which allows for speed regulation down below 1% error margins. What makes this even better for some industries is the sensorless approach that gets rid of those fragile encoders altogether. Instead, systems analyze current and voltage data on the fly. This matters a lot in dangerous settings where equipment failures can be catastrophic, think mines or chemical processing facilities where replacing traditional sensors would require shutting down operations entirely.

IoT and Smart Monitoring for Predictive Maintenance

Embedded IoT sensors track parameters like winding temperature, vibration patterns, and harmonic distortion, flagging anomalies before failures occur. Factories using these systems reduced unplanned downtime by 41% and maintenance costs by 28% annually. Cloud-based dashboards aggregate data across motor fleets, enabling trend analysis for lifecycle optimization.

Next-Gen Materials and Design Improvements Boosting Efficiency

Amorphous alloy stators and graphene-enhanced windings are pushing induction motor efficiencies beyond IE5 standards. These materials reduce eddy current losses by 60–70% while withstanding temperatures exceeding 180°C. 3D-printed cooling channels improve heat dissipation by 40%, enabling compact designs without compromising output—critical for space-constrained automated assembly lines.

Key Industrial Applications and Role in Smart Manufacturing

Widespread Use in Mining, Oil & Gas, and Heavy Manufacturing

Induction motors serve as workhorses in resource-intensive industries, with the industrial segment capturing 35.8% of smart motor adoption in 2023 (SNS Insider). Their ability to operate reliably in extreme temperatures, dusty mining tunnels, and high-vibration oil rigs makes them indispensable for heavy machinery like drilling systems and mineral processing equipment.

Powering Conveyors, Pumps, Cranes, and Crushers

These motors excel in driving material-handling systems critical to industrial workflows:

- Conveyors: Maintain consistent speed under variable loads

- Pumps: Handle viscous fluids in chemical plants without overheating

-

Crushers: Deliver high starting torque to break down raw materials

Their rugged construction minimizes downtime in 24/7 production environments.

Enabling Industry 4.0: Integration in Automated and Digital Factories

Induction motors these days are basically smart devices within factory settings, sending all sorts of operational info through those little IoT sensors right into central monitoring systems. The real game changer here is how this setup helps with predicting when something might go wrong before it actually does. Some studies from Siemens back in 2024 showed factories could cut down unexpected shutdowns by almost half using this approach. Throw in some AI analysis tools and suddenly these motors aren't just running machines anymore - they're helping save energy throughout entire production lines. Plus, everything stays nicely timed up with robots working alongside them on the floor. Makes sense why so many manufacturers are jumping on board with this tech nowadays.

FAQ

What are IE3 and IE4 standards?

IE3, or International Efficiency 3, refers to premium efficiency standards for industrial motors, whereas IE4 indicates super premium efficiency. These standards ensure that motors consume less energy and operate more efficiently than older models.

Why are induction motors preferred in industrial settings?

Induction motors are robust, durable, and have low maintenance needs due to their simple design. They are capable of handling extreme conditions and have high energy efficiency, making them suitable for various industrial applications.

How do Variable Frequency Drives (VFDs) improve motor efficiency?

VFDs optimize the speed and torque of induction motors, reducing the energy consumed during operations. This fine control helps in adapting to varying workloads, enhancing overall efficiency and reducing operating costs.

What role do induction motors play in achieving sustainability goals?

Induction motors aligned with IE3 and IE4 standards significantly reduce energy consumption and carbon footprint. They support environmental policies and ESG goals by lowering CO2 emissions and increasing energy efficiency in industrial processes.