How Induction Motors Power Industrial Ventilation Systems

Phenomenon: Prevalence of Induction Motors in HVAC and Fan Applications

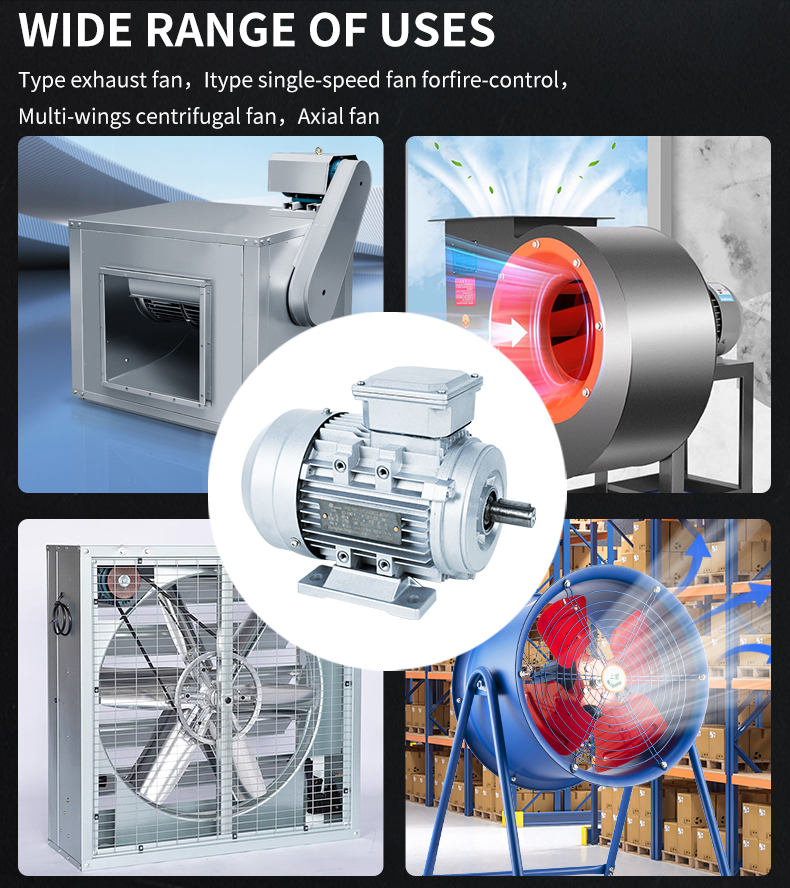

Over 78% of industrial ventilation systems rely on induction motors due to their unmatched reliability in continuous operation (Knowledge Sourcing 2024). These motors drive critical components like centrifugal fans, axial blowers, and rooftop exhaust units across manufacturing plants and commercial HVAC systems. Their dominance stems from three key factors:

- Load adaptability: Maintain 85%+ energy efficiency across variable airflow demands

- Duty cycle endurance: Operate 24/7 without performance degradation in dusty or humid environments

- Cost-effectiveness: 40% lower lifetime maintenance costs compared to brushed alternatives

Urbanization accelerates adoption—emerging economies now install 2.3 million industrial fans annually requiring robust motor solutions (2024 HVAC Technology Report).

Principle: Why Induction Motors Are Suited for Ventilation Loads

The working principle of electromagnetic induction enables critical performance advantages:

- Brushless design eliminates arcing risks in explosive atmospheres, such as paint booth exhaust systems

- Rotating magnetic field synchronizes with AC frequency (50/60 Hz), ensuring precise RPM control for consistent airflow

- Squirrel cage rotors endure 200,000+ start/stop cycles—essential for demand-responsive ventilation

This inherent simplicity supports 92% uptime in industrial settings according to motor failure rate studies. When paired with modern variable frequency drives (VFDs), induction motors reduce ventilation energy costs by 18—35% through dynamic load matching.

Single-Phase vs. Three-Phase Induction Motors in Ventilation Applications

Applications of Single-Phase Induction Motors in Fans and Blowers

Single-phase induction motors power most small-scale ventilation systems—including residential exhaust fans, ceiling blowers, and compact HVAC units—due to their cost-effectiveness and compatibility with standard 120V/240V supplies. Using split-phase or capacitor-start mechanisms, they deliver sufficient torque (typically 0.25—1 HP) for airflow demands under 3,000 CFM. A 2022 ASHRAE study found these motors in 78% of sub-5kW ventilation devices in commercial buildings, favored for their quieter operation (<55 dB) in offices and retail spaces. However, their 80—85% efficiency limits suitability for high-duty-cycle applications.

Three-Phase Induction Motors in Industrial Applications: Dominance in Large-Scale Ventilation

Three-phase induction motors drive 91% of industrial ventilation systems requiring 5—500 HP, according to the 2024 Motor Efficiency Report. Their balanced rotating magnetic field sustains 92—95% efficiency in ducted exhaust fans, centrifugal blowers, and rooftop HVAC units moving over 10,000 CFM. Key advantages include:

- Smooth torque delivery for belt-driven systems under variable static pressure

- Compatibility with VFDs for dynamic airflow adjustments

- 40,000—60,000 hour lifespans in continuous operation

A Texan plastics plant reduced energy costs by 30% after replacing DC motors with three-phase models in 120 industrial exhaust fans (SE.com case study, 2023).

Efficiency Trade-offs Between Single-Phase and Three-Phase Induction Motors

While three-phase motors offer 8—12% higher operational efficiency, single-phase variants remain practical where three-phase power is unavailable. The table below summarizes key trade-offs:

| Factor | Single-Phase | Three-Phase |

|---|---|---|

| Typical Efficiency | 80—85% | 92—95% |

| Startup Torque | 150—250% rated torque | 200—300% rated torque |

| Lifespan at 24/7 Use | 25,000—35,000 hours | 40,000—60,000 hours |

For ventilation loads under 5 HP, single-phase motors offer 18% lower upfront costs but incur 22% higher lifetime energy expenses versus three-phase alternatives (Motor Systems Report, 2023).

Performance and Reliability of Induction Motors in Continuous Operation

Industrial Applications of Induction Motors: Focus on Long-Term Reliability

Induction motors work really well for industrial ventilation systems that need to run all day every day even when the workload changes constantly. These motors don't have brushes which means there's less parts wearing out over time. Plus, they come with sealed bearings that keep out dust and other particles typically found in factories. Looking at data from last year on big industrial blowers, around four out of five induction motor units kept running past 50 thousand hours without needing anything serious fixed. The latest improvements in predictive maintenance tech let operators check winding temps and track vibrations as they happen, not after something goes wrong. This proactive approach actually adds about an extra fifth to a third more lifespan to these motors compared to waiting until something breaks before fixing it.

Performance Comparison: Induction Motors vs. Other Motor Types in High-Load Blowers

In industrial blower applications, induction motors outperform alternatives in key areas:

- Torque Efficiency: Maintain 92% torque output at 75% load capacity, versus 84% for universal motors

- Heat Tolerance: Class F insulation allows continuous operation at 155°C ambient temperatures, exceeding DC motor limits by 25°C

- Cost Profile: Deliver 30—40% lower lifecycle costs than permanent magnet synchronous motors

Their self-regulating speed response under variable airflow demands reduces reliance on complex controls. A 2022 study of mine ventilation systems showed induction motors cut unexpected downtime by 62% compared to switched reluctance motors.

Case Study: Energy Efficiency Gains Using Induction Motors in Cooling Fans

A pharmaceutical plant retrofit replaced aging shaded-pole motors with a 500HP induction motor in its HVAC cooling towers, achieving significant improvements:

| Metric | Improvement | Source |

|---|---|---|

| Energy Consumption | 15% Reduction | Plant Energy Audit 2023 |

| Noise Levels | 8 dBA Drop | ISO 4871 Compliance Test |

| Maintenance Intervals | 2x Extension | Predictive Maintenance Research |

The upgrade delivered full ROI within 14 months through energy and labor savings, maintaining 99.6% uptime during peak summer loads.

Optimizing Energy Efficiency with VFDs and Modern Control Strategies

Trend: Integration of VFDs with Induction Motors for Dynamic Load Control in HVAC

These days, many industrial ventilation setups are starting to combine induction motors with those variable frequency drives we call VFDs. The main reason? Better control over how much air moves around. When thermal loads change, these drives adjust motor speeds on the fly, so they don't keep running at full blast all day long. Cut down motor speed by about 20 percent and watch power usage drop almost half way because of how speed relates to power consumption cubically. Facilities that have upgraded their systems report savings anywhere from 20 to 60 percent on heating, ventilation and cooling expenses according to recent studies published last year in Energy Sustainability Reports.

Strategy: Optimizing Fan Performance with Induction Motor Drives

VFDs enhance fan efficiency by aligning motor torque with actual airflow needs. Traditional damper or valve control forces motors to run at full speed, wasting energy during partial-load conditions. In contrast, VFD-driven systems dynamically adjust speed:

| Control Method | Speed Adjustment | Energy Efficiency | Maintenance Costs |

|---|---|---|---|

| Valve/Damper Control | Fixed | Low | High |

| VFD Optimization | Variable | High | Low |

This adaptive control reduces mechanical stress on bearings and windings, extending motor lifespan by up to 30% in demanding environments like foundries and data centers.

Trend: Adoption of Induction Motors in Modern Exhaust Fan Systems

Three phase induction motors have become pretty much standard equipment for modern smart exhaust systems because they work so well with IoT based automation setups. Take places where air quality changes all the time like chemical manufacturing sites or busy restaurant kitchens. When things get really smoky or steamy, VFD controlled motors kick in to boost airflow exactly when needed, but they don't waste power sitting there doing nothing when conditions calm down. The numbers tell an interesting story too. Most companies report getting their money back within about two to three years from running these systems, mainly thanks to lower electricity bills and fewer breakdowns messing up operations.

Frequently Asked Questions

What makes induction motors so prevalent in industrial ventilation systems?

Induction motors are popular because they offer high reliability, energy efficiency over various loads, operational durability, and cost-effectiveness.

How do induction motors differ between single-phase and three-phase applications?

Single-phase induction motors are typically used in smaller applications due to their lower cost and compatibility with standard power supplies, while three-phase induction motors handle larger loads with greater efficiency.

Can VFDs really make a difference in energy savings for systems with induction motors?

Yes, integrating Variable Frequency Drives (VFDs) with induction motors allows dynamic control over motor speeds, which can significantly reduce energy consumption and improve efficiency.

Table of Contents

-

How Induction Motors Power Industrial Ventilation Systems

- Phenomenon: Prevalence of Induction Motors in HVAC and Fan Applications

- Principle: Why Induction Motors Are Suited for Ventilation Loads

- Single-Phase vs. Three-Phase Induction Motors in Ventilation Applications

- Applications of Single-Phase Induction Motors in Fans and Blowers

- Three-Phase Induction Motors in Industrial Applications: Dominance in Large-Scale Ventilation

- Efficiency Trade-offs Between Single-Phase and Three-Phase Induction Motors

- Performance and Reliability of Induction Motors in Continuous Operation

- Optimizing Energy Efficiency with VFDs and Modern Control Strategies

- Frequently Asked Questions